FITTINGS

FITTINGS

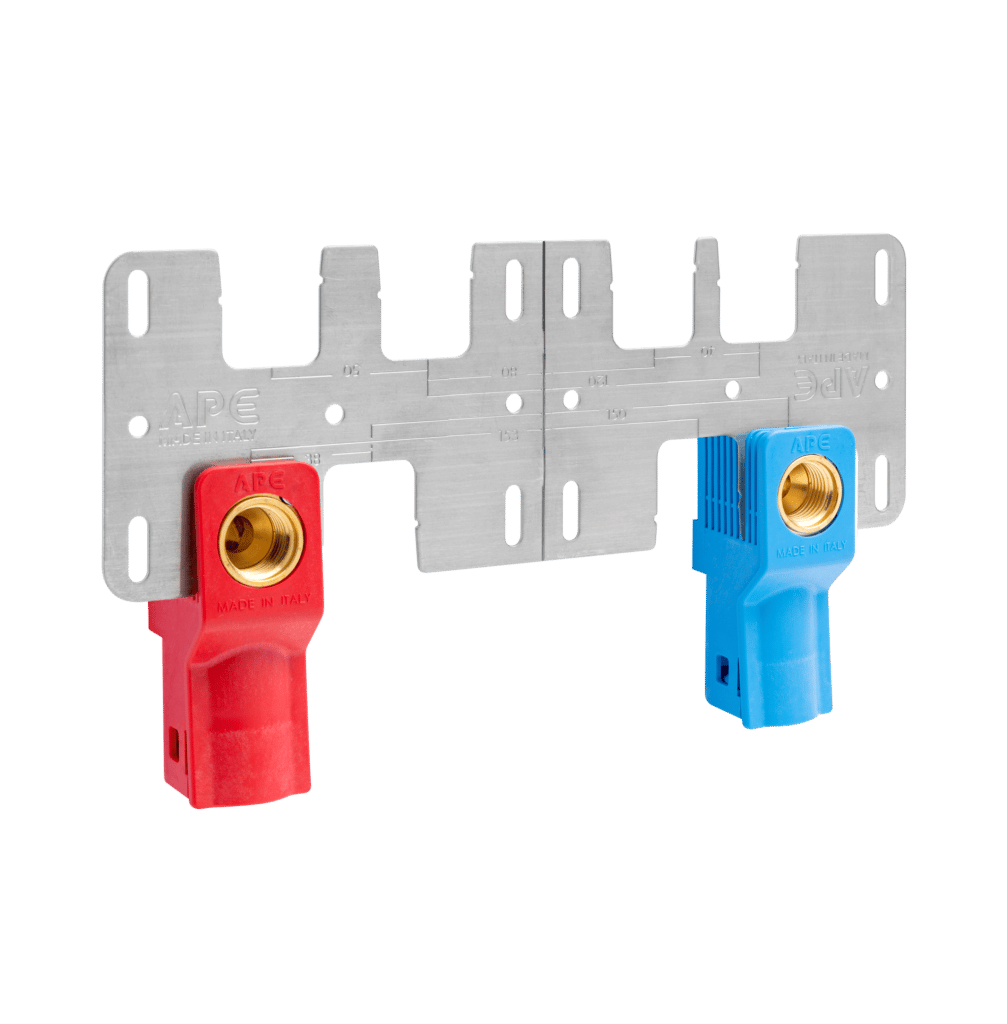

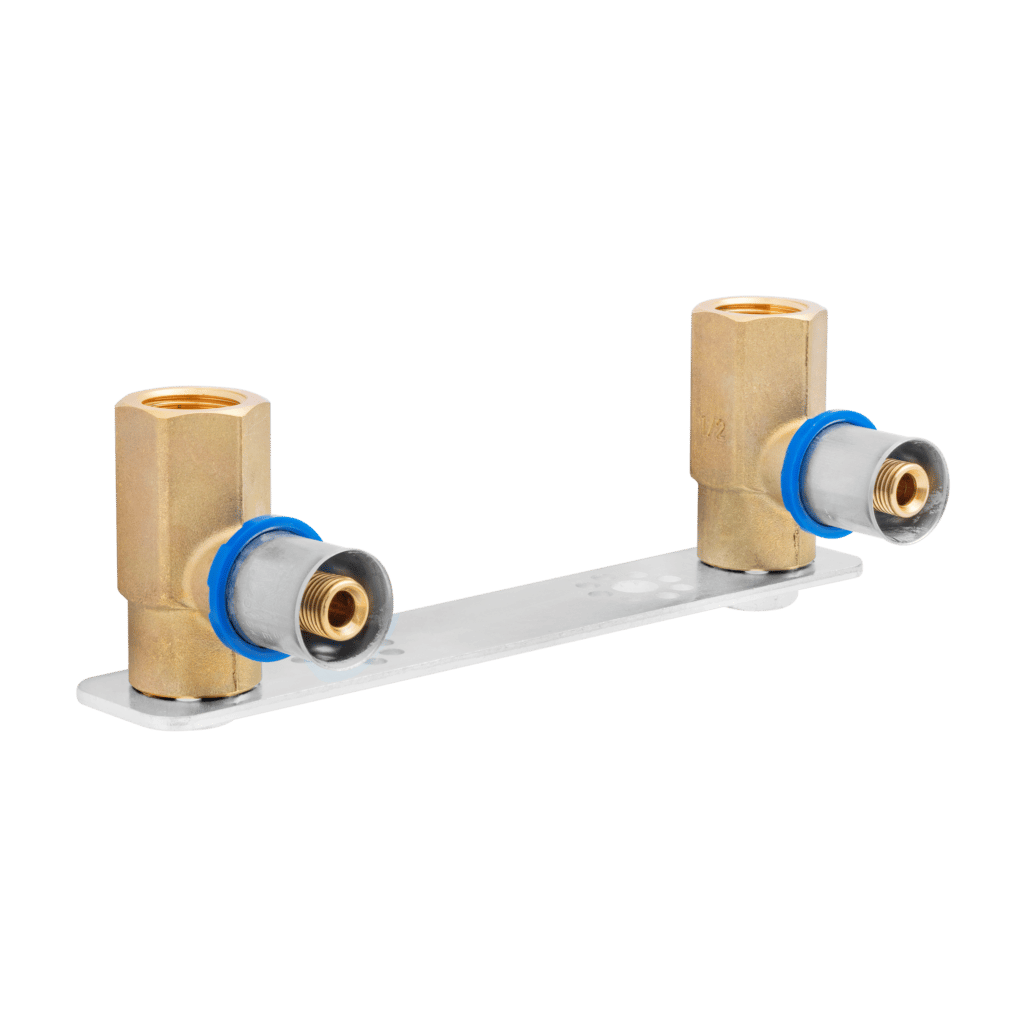

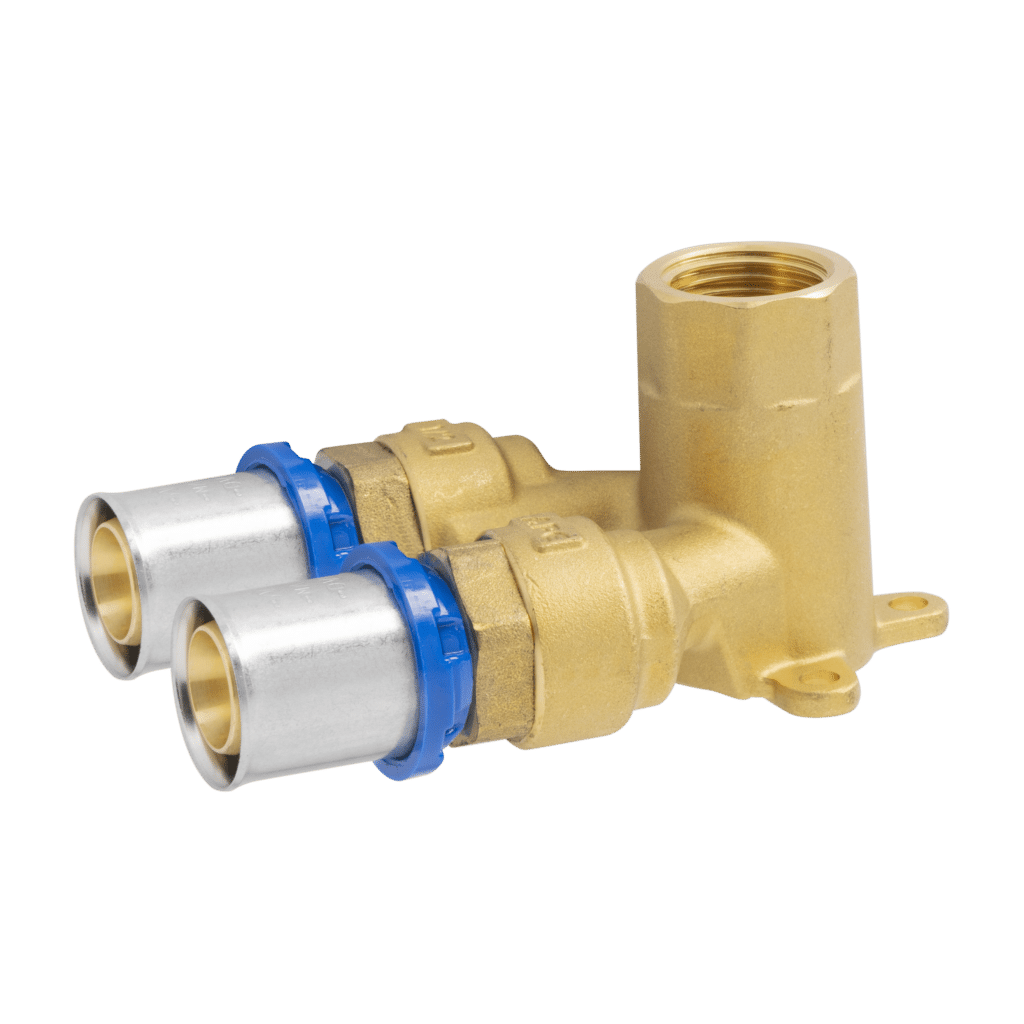

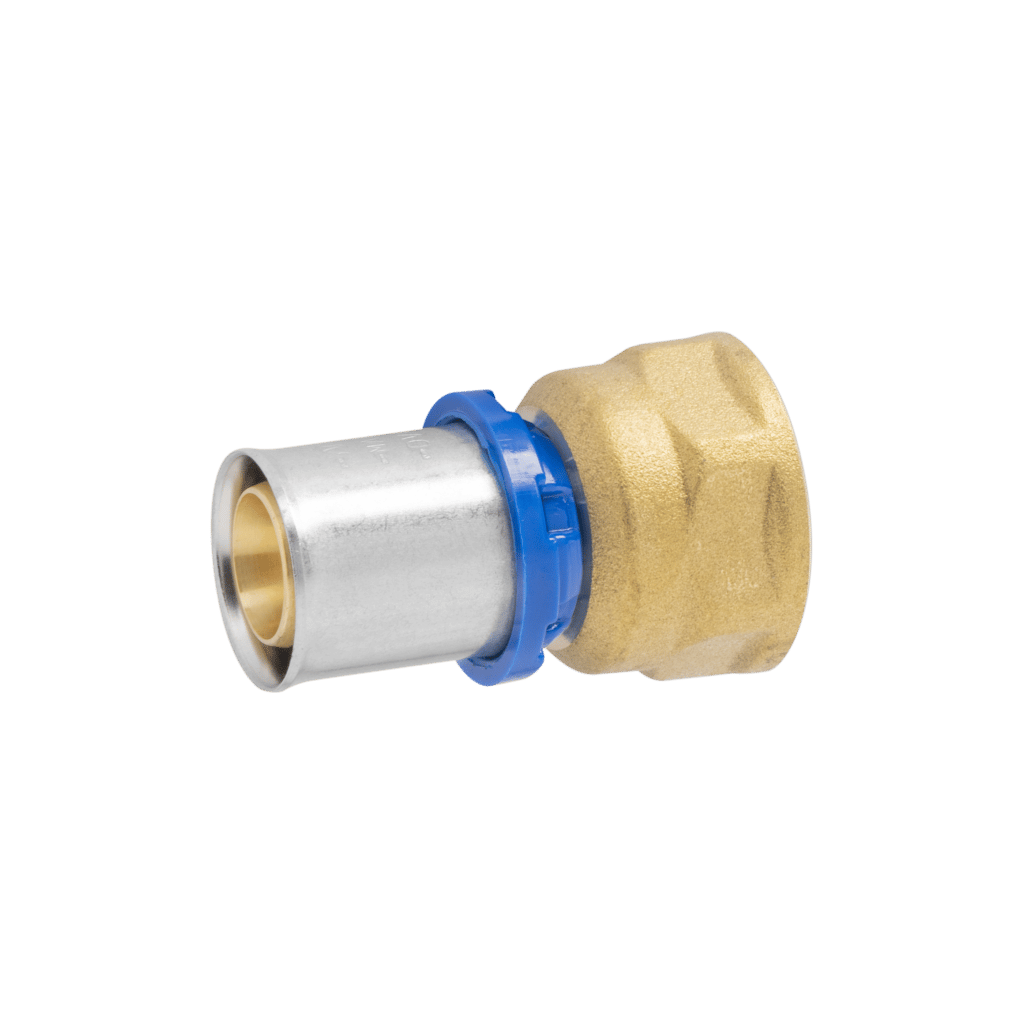

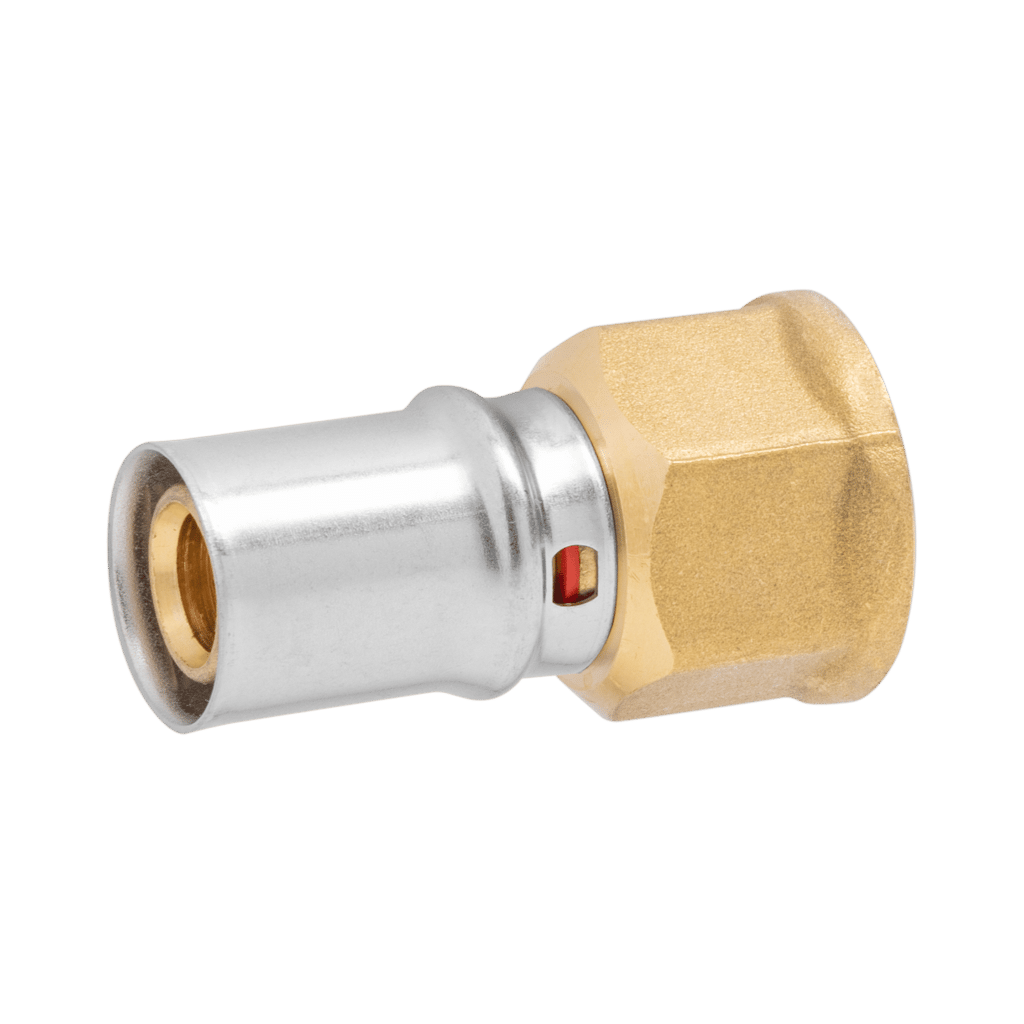

The wide range of fittings proposed by APE RACCORDERIE, both pressing and tightening fittings, includes shapes for every need and use, as well as manifolds for both domestic hot water and heating. The wide range proposed by APE encompasses all the company’s technical/productive know-how,

thanks to strictly MADE IN ITALY internal production, where every step, from the raw material to the finished product, is carefully monitored through stringent quality controls.

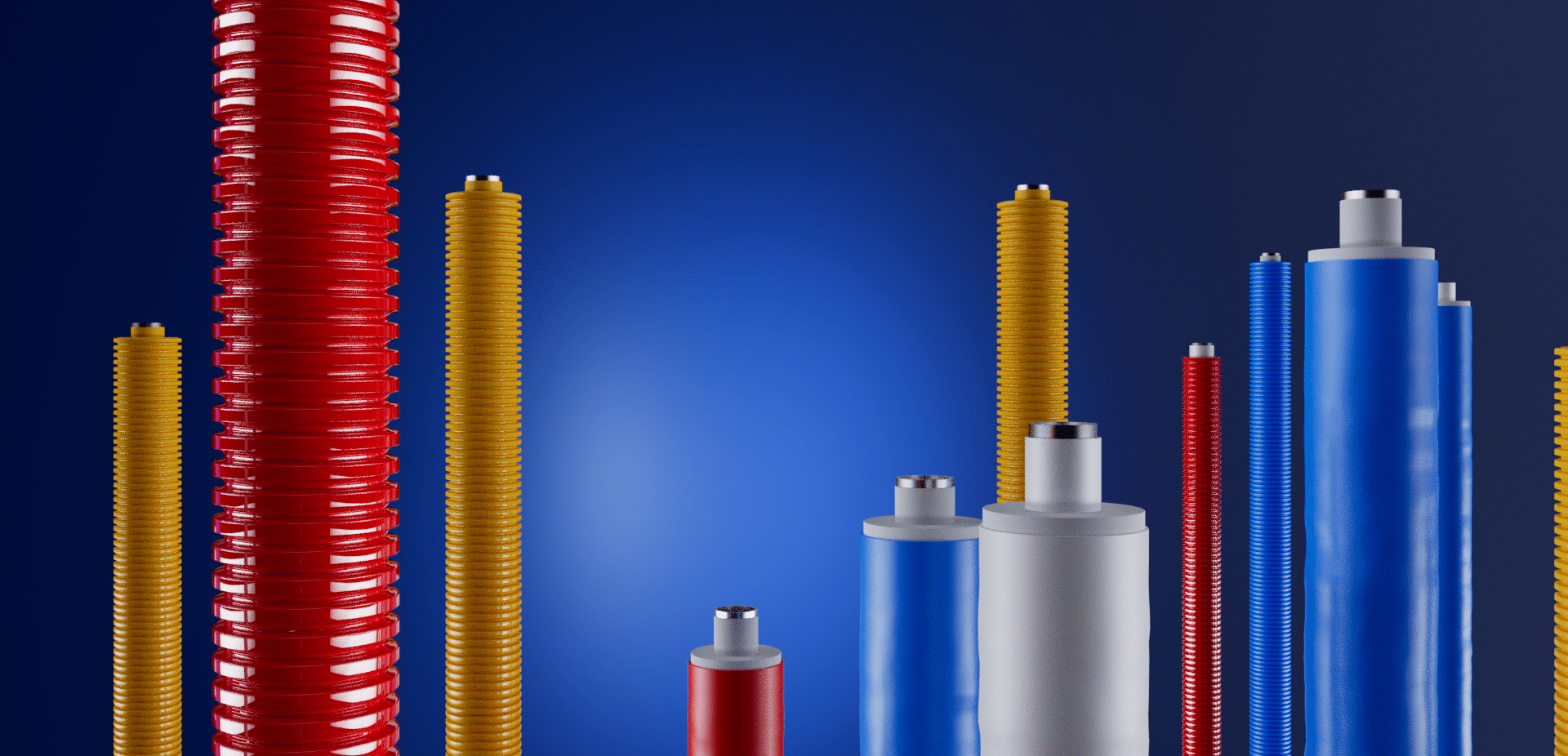

MULTILAYER PIPES

MULTILAYER PIPES

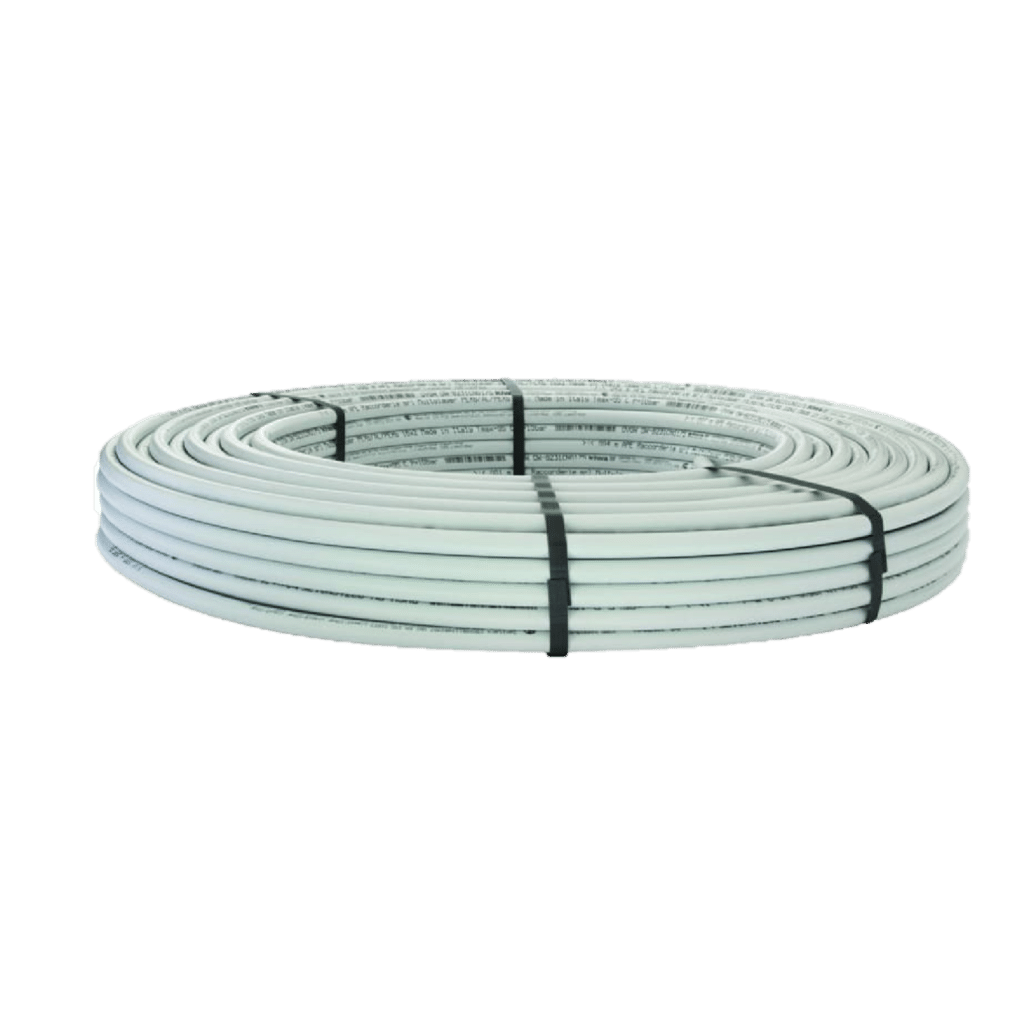

APE manufactures MULTILAYER PE-xB/AL/PE-Xb multilayer pipes in different diameters, suitable for conveying both technical water and water for sanitary and drinking use. The pipes have passed all UNI EN ISO 21003 tests and obtained the certicates of major international bodies such as DVGW, KIWA, WRAS, ATG, KOMO, DINCERTCO, AFNOR and AENOR. The range also includes the coated version, suitable for heating and cooling, and the sheathed version for countries of Northen Europe. The entire production is guaranteed by the high expertise and professionalism of the Ape Raccorderie quality system.

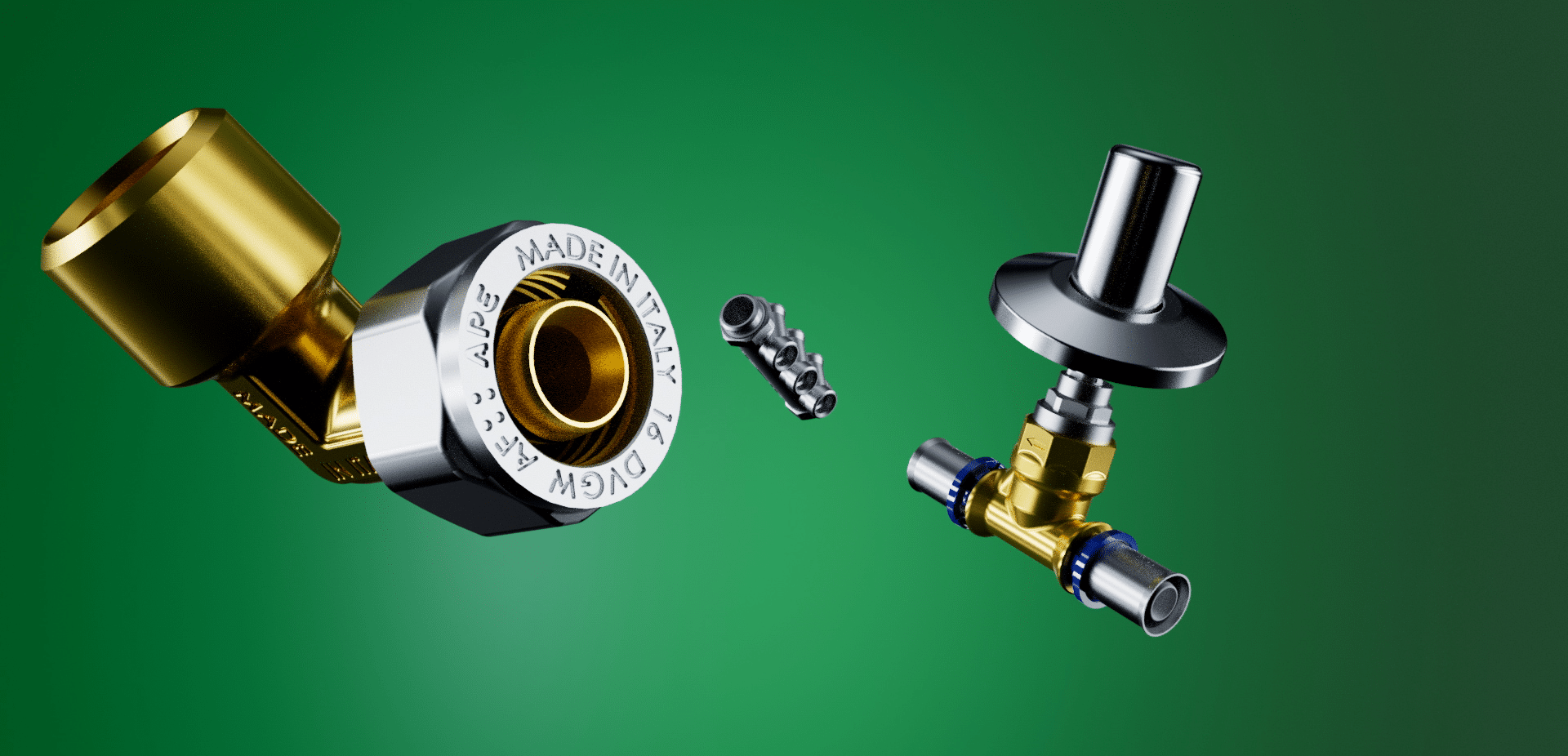

GAZ

GAZ

The Gas section includes the entire system for the distribution of gas and LPG according to UNI 7129 standard, starting from the AP GAS press-fitting series, to the bare or sheathed multilayer pipe, distribution manifolds, right up to the trace box and ball valve kits. The MULTYGAS APE pipe-fitting system, made entirely in our facility, has passed all UNI 11344 tests and obtained the Kiwa Quality certificate.

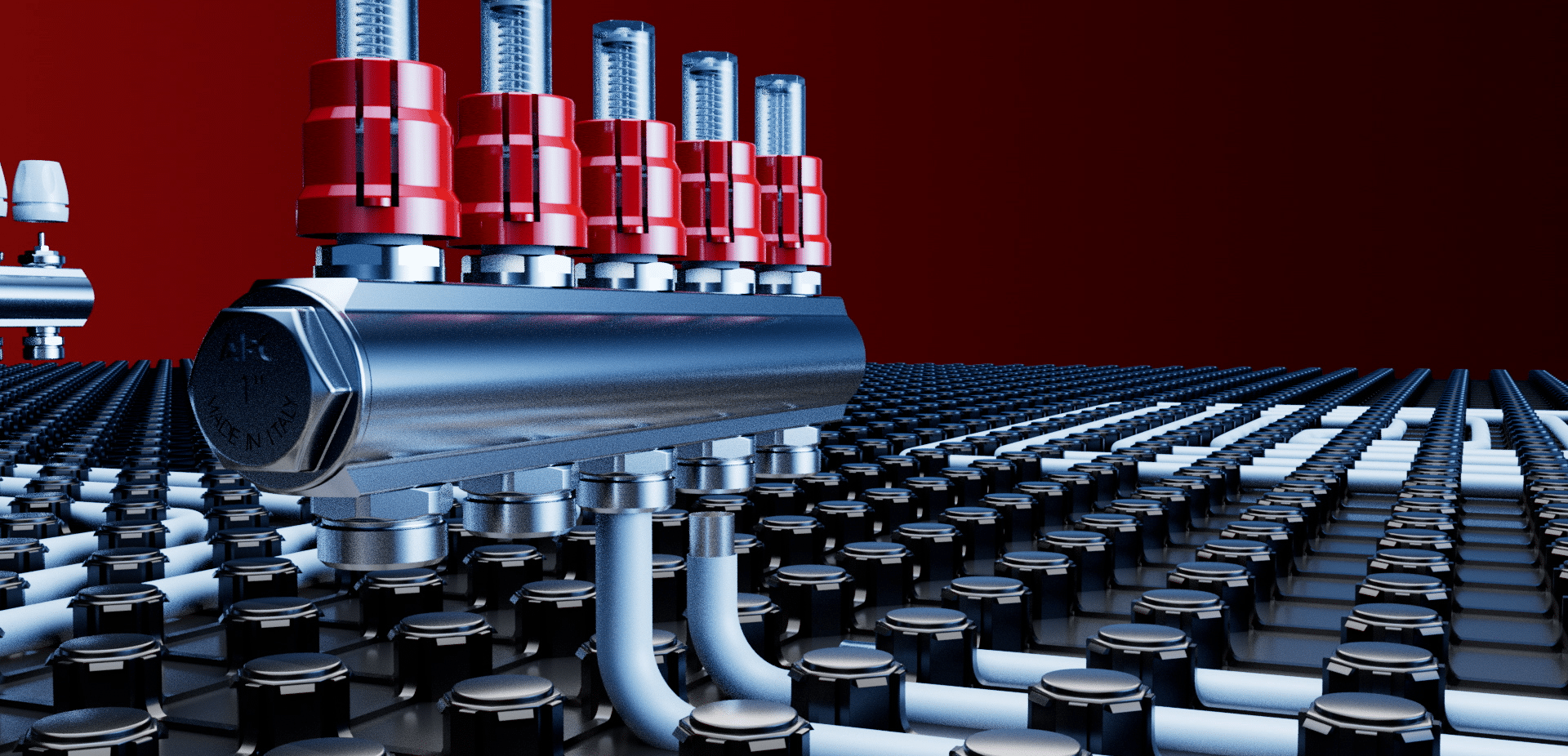

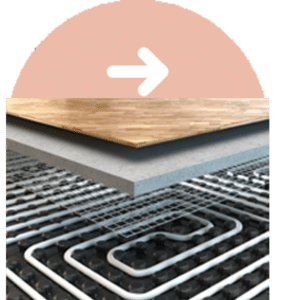

THERM

THERM

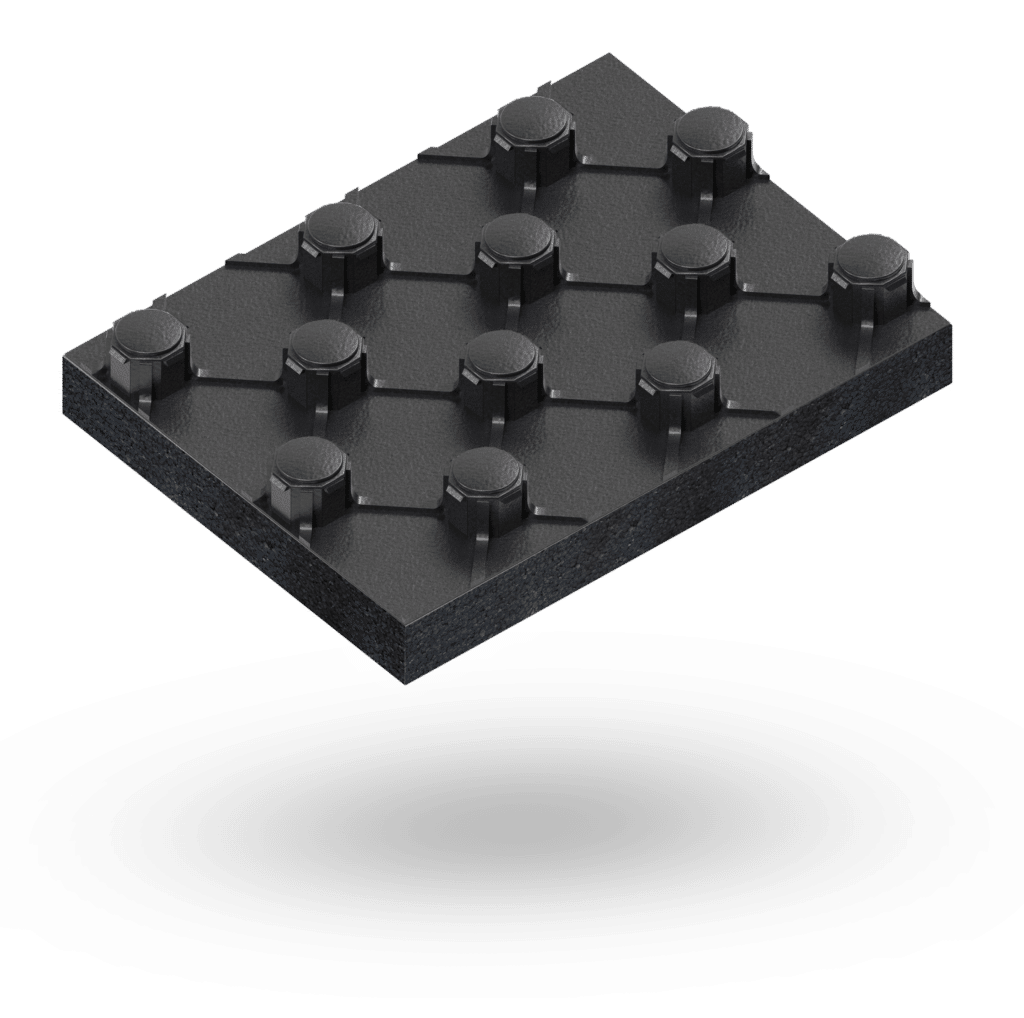

APE Raccorderie, always attentive to the well-being of people and to reducing energy consumption, has developed the THERM section that includes radiating under floor/wall/ceiling heating/cooling and relative energy metering accessories; this section is in continuous evolution to better meet the needs of the market and technological innovation.